Description

Introduction

The film begins with an introduction that features the Sismak logo with changing subtitle text. The subtitle text highlights the most important priorities: people and product. We are in a car driving down curvy road from driver point of view and up to Sismak faculty. The introduction and the conclusion are the same to ensure that the video is able to loop. In the introduction, we introduce the idea that steering boxes guide both vehicles and people. The steering box is one of the most important safety components on the vehicle. As such, safety, people and product quality are a top priority. We want to create the perception that our viewpoint is not just of a street but wider point of view. The scene includes shots taken from the Sismak vehicles driving on the road and stock video of a curvy road.

Scene One | Company Overview

In this scene, we compare the Sismak integrated management systems to a home where all the units are gathered under the roof and constantly interacting. In addition to providing an overview of the facility, the scene highlights the Integrated Management Systems across all of the departments involved in designing and manufacturing a product. Lastly, text will feature the various certifications. The scene includes the exterior drone shots. The transition from the exterior to interior may include the hand-held drone shots. Played in reverse, the handheld shots will provide a tour of the facility with text overlay featuring our keyword and phrases. If required, we may use the ‘Minority Report’ control panel to provide additional information.

Key words and phrases:

“Everything starts and ends with people” | “Hayata Yön Ver” | “State of the Art” | “Technology” | “Established 1980” | “10,000 square meters” | “Give Direction to Life” | “Advanced” | “Steering Systems” | “Steering Box” | “Safety” | “Quality” | “Big Picture” | “Customer Focus” | “Leadership” | “Employee Participation ” | “Process Approach” | “Continuous Improvement” | “Data-Driven” | “Decision Making” | “Relationship Management” | “Protecting the Environment” | “ISO 14001” | “Sustainability” | “Integrated Management Systems”

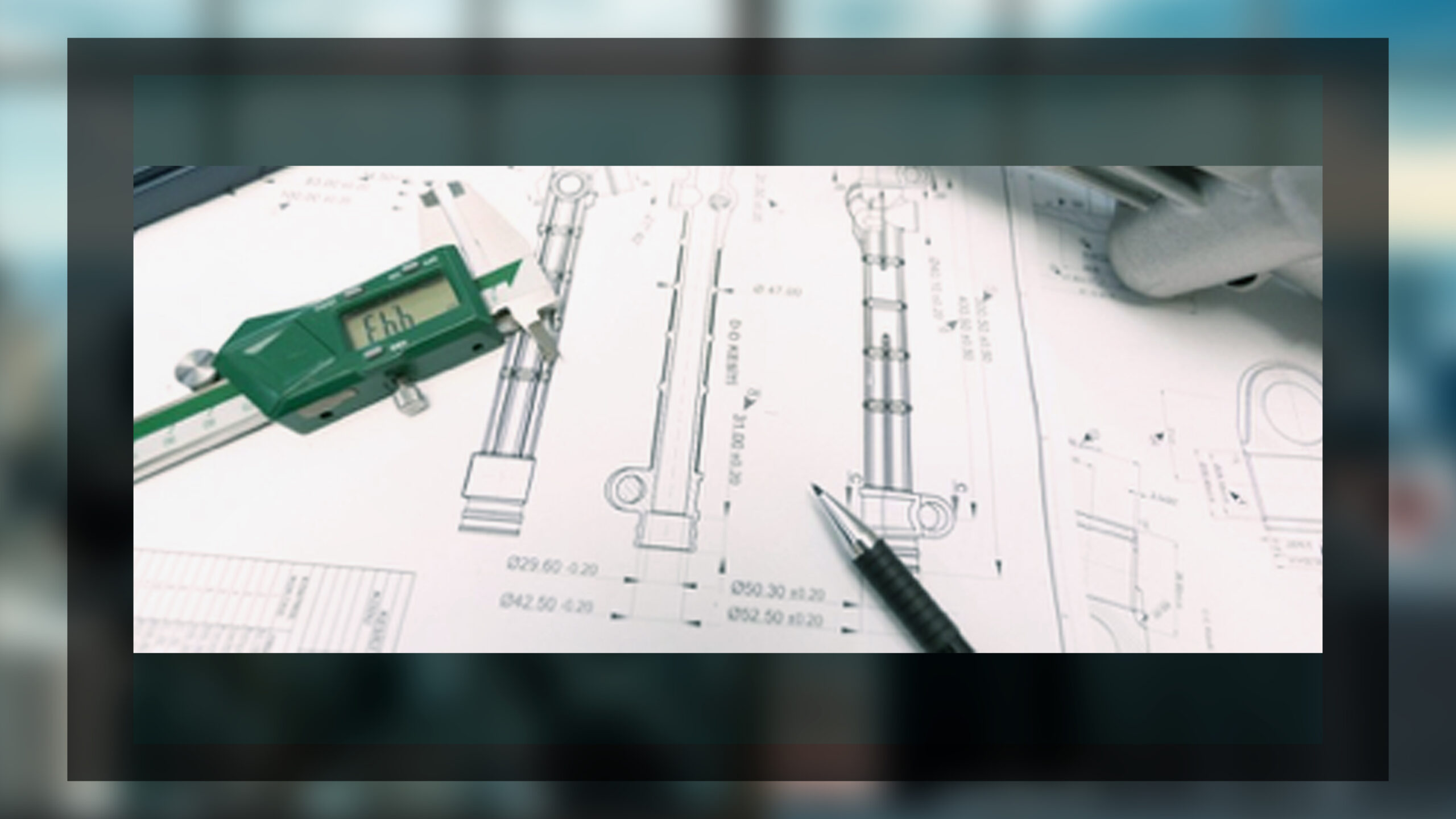

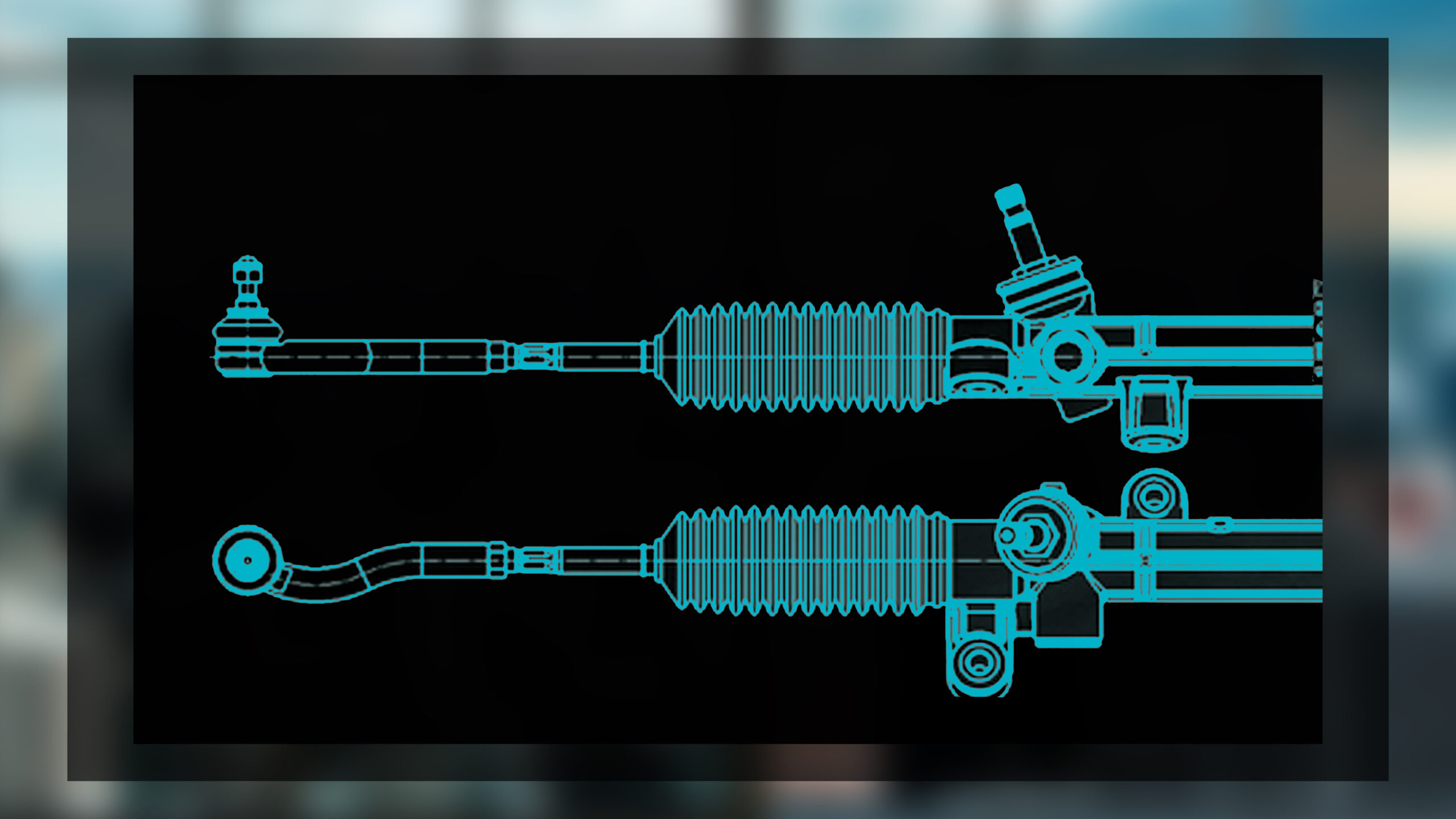

Scene Two | Engineering

The scene begins with the tabletop shot from the laboratory. Scene two highlights all of the activities involved in designing a product from concept inception to prototyping and testing. The scene will include the 3D models provided by Sismak. If required, we can use stock video of a computer and include the various screen shots provided by Sismak.

Key words and phrases:

“Engineering” | “Research and Development” | “Design” | “Concept” | “Prototype” | “Inception” | “Teamwork” | “Creation” | “Idea” | “Modeling”

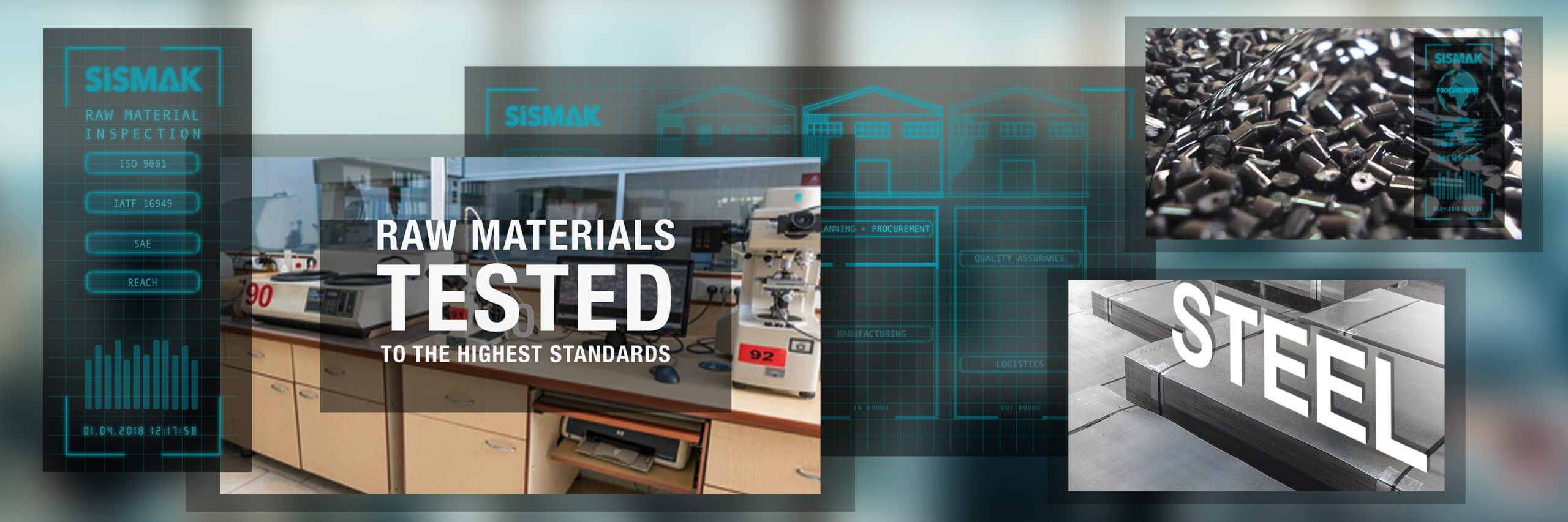

Scene Three | Planning and Procurement

In scene three, things start to speed up. We see images of the raw materials and components. The scene also emphasizes the testing of raw materials and components prior to manufacturing. There are three key raw material shots: (1) Metal components (2) Plastic components dropping (3) Steel bars.

Key words and phrases:

“Planning” | “Procurement” | “ERP – Enterprise Resource Planning” | “Raw Materials” | “Input” | “Testing” | “MRP – Material Requirements Planning” | “Components”

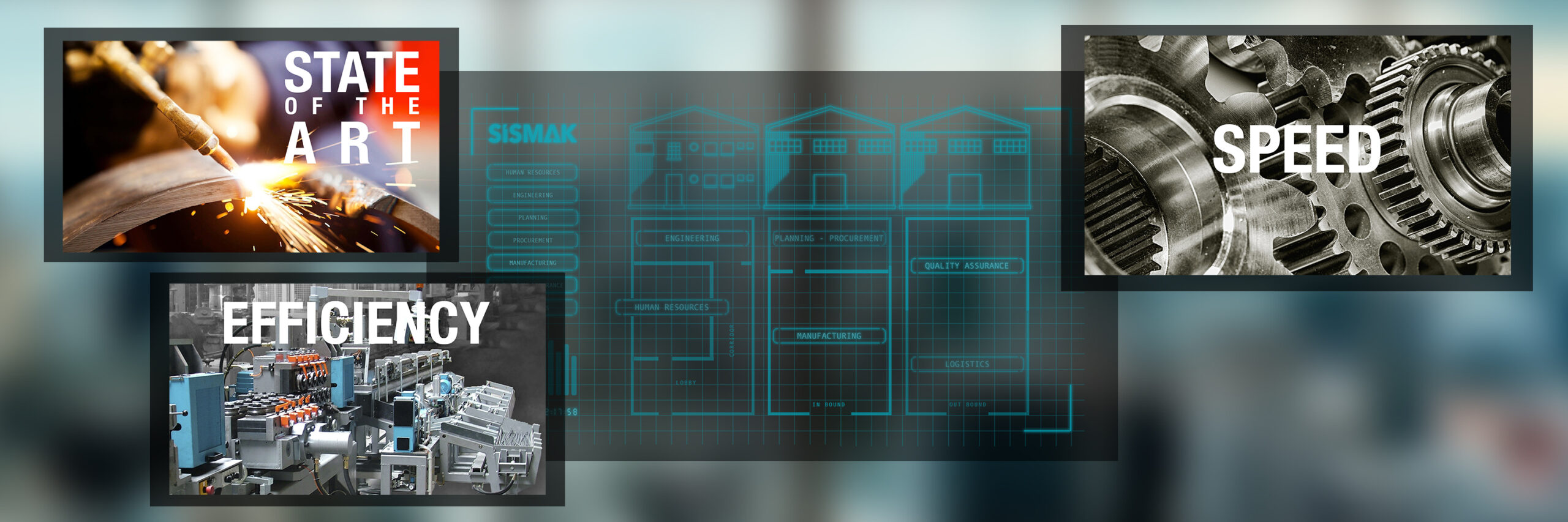

Scene Four and Five | Manufacturing, Assembly and Quality Assurance

In scene four, the film reaches maximum speed. The scene has three important sections: (1) manufacturing of components (2) assembly of components (3) quality assurance of final product. In the manufacturing scenes, there is no shot order – instead, all things are happening at the same time. ‘Lean’ manufacturing (shot: ultra-violet crack detection) and PMI (shot: green light) are important concepts in the manufacturing scenes. We transition from the manufacturing to assembly with a shot of all of the procured, manufactured and tested components waiting to be assembled. The scene ends with four quality assurance shots: three from the laboratory and one from the factory floor (shown in the last row below).

Key words and phrases:

“Technology” | “Efficiency” | “Productivity” | “Flexibility” | “Quality” | “Capacity” | “350,000 pieces annually” | “Automated” | “Production” | “Manufacturing” | “Lean” | “PMI – Product Manufacturing Information” | “C and C” | “Straightening” | “Assembly” | “Grinding” | “Brushing” | “Ultraviolet Crack Detection” | “ISO 9001” | “IATF 16949”

Scene Six | Fulfillment

In the final scene, the product has been assembled and finished final testing and inspection. It is now ready for packaging. We see the product packaging and barcoding. Branded cartons will have graphic overlays featuring key words and phrases.

Key words and phrases:

“Fulfillment | “30 countries” | “Four Continents” | “OEM” | “In Time Delivery” | “Customer Satisfaction” | “Worldwide” | “Partners”